Cannabis and indoor agriculture can slash overhead costs with energy efficiency

(ACEEE blog, 30 May 2019) As the market for indoor agriculture in North America surges, businesses, growers, and states are finding innovative ways to slash energy costs that demonstrate the potential for much greater savings.

Indoor agriculture — primarily flowers, herbs, lettuces, tomatoes, berries, and cannabis in greenhouses and other buildings — is a rapidly expanding and evolving industry across North America. Known as controlled environment agriculture (CEA), this energy-intensive industry was valued at roughly $47 billion in 2017. While its compound annual growth rate is projected at 3.4% for 2018-2023, some markets anticipate even faster growth, such as cannabis, with a projected 14.4% annual increase through 2025. As the industry expands, so does its energy use.

The latest issue brief in our Emerging Opportunities in Buildings series provides a snapshot of energy consumption in CEA facilities and the significant efficiency opportunities available. Reducing energy costs is vital to the industry’s success, because they account for as much as 25% of operating costs.

Efficiency investments can provide an important boost to the bottom line. While the food and flower crops grown in CEA facilities are typically higher in value than commodity crops, margins for growers are still relatively low. And in the cannabis sector, experience has shown that the high prices common when a state first legalizes adult use tend to collapse after a few years as the market becomes saturated and stabilizes.

Working closely with growers, equipment manufacturers have developed efficient LED lighting systems for different facility types including greenhouses, single-tier container farms, and multi-layer stacked vertical farms. HVAC manufacturers are producing specialized equipment to provide the precise climate, humidity, and airflow required for plant health, pest control, and mold prevention. These technologies allow growers to produce multiple crops over the course of the year and, in some cases, to produce significantly more product per acre of land and gallon of water than traditional agriculture.

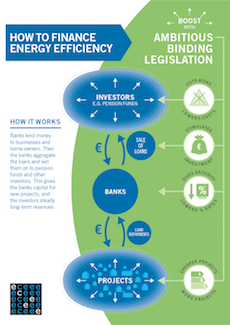

These technical developments can reduce energy use by 30-50% or more, but substantial barriers have limited their broad adoption. Like many new industries, CEA faces a lack of access to capital as businesses work to demonstrate profitability to lenders and investors. Capital constraints are even more pronounced for cannabis growers, given federal limitations on banking for the cannabis industry. Limited data on energy use make it harder for growers to weigh the potential benefits of energy efficiency investments against perceived risks associated with adopting new technologies and practices or dealing with the disruptions of a retrofit project.